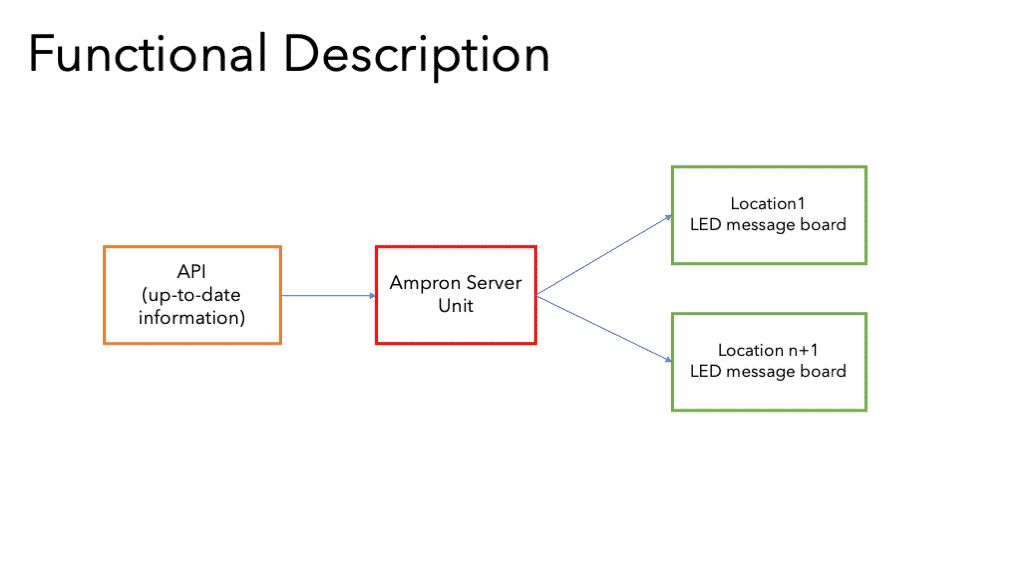

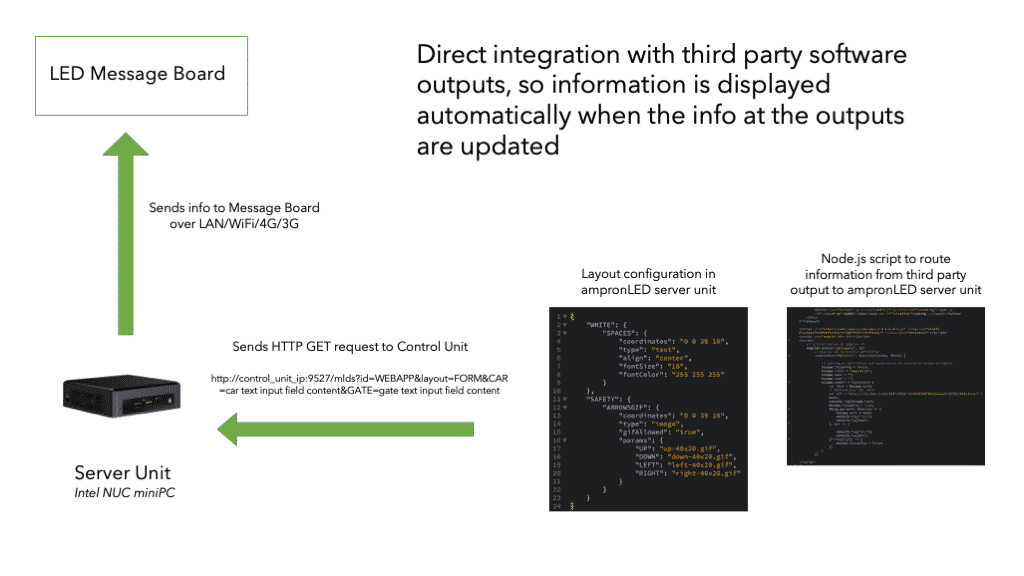

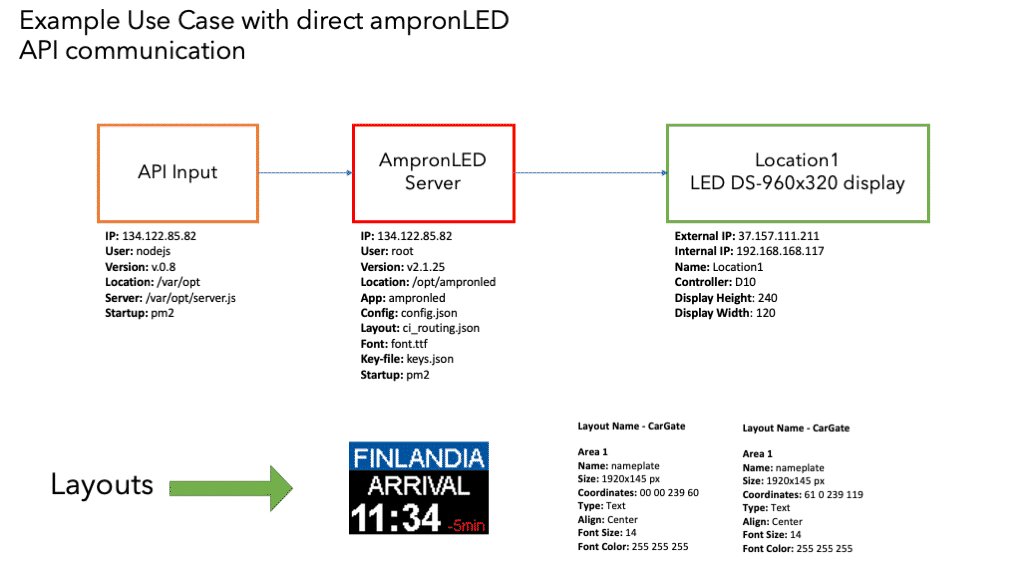

OPTION 1 – ampronLED communication protocol

Direct integration with third-party software outputs, so information is displayed automatically when the info at the outputs are updated.

Biggest advantage of this approach is full automation, based on the triggers on a software level. That removes the need for manual labour and people can focus on the operations.

Another advantage is the minimum hardware needs (compared with the digital signage based solutions) at the solution level, that means less hardware to fail.

The downside of this option is the need for more thought-out process on a level of thinking through all the integrations and automation. Also the need for the software developers who would make the integrations.

From the content perspective, this control option is limited to a pictograms (pictures), GIF`s and freeform text.

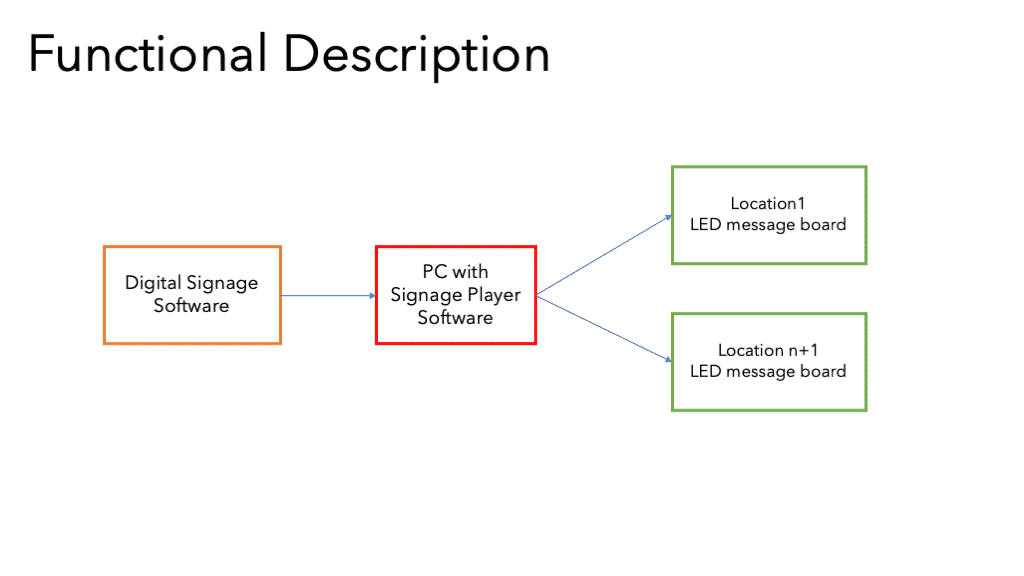

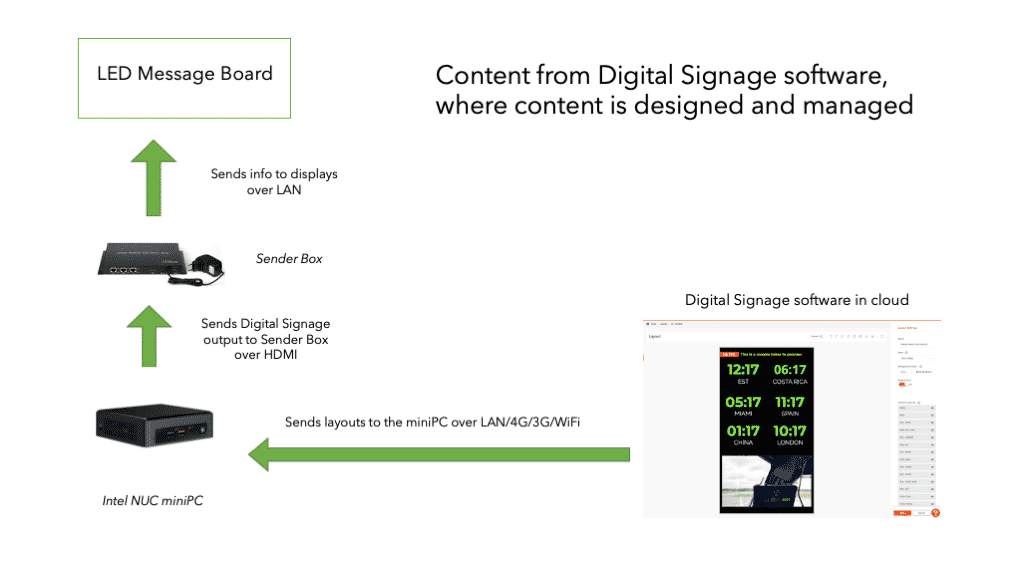

OPTION 2 – Digital Signage Player

Separate computer with signage software, where content is designed and managed. This approach is good for those who need to display videos, manage commercials or have the need for cloud-based user interface.

Also for those who already have the signage player solution implemented in their organisations and want the simplest learning curve for your people.

Advantage of this solution is richer media visualisation possibilities. Downside is the amount of needed hardware that makes the use in operational environment risky and unreliable.

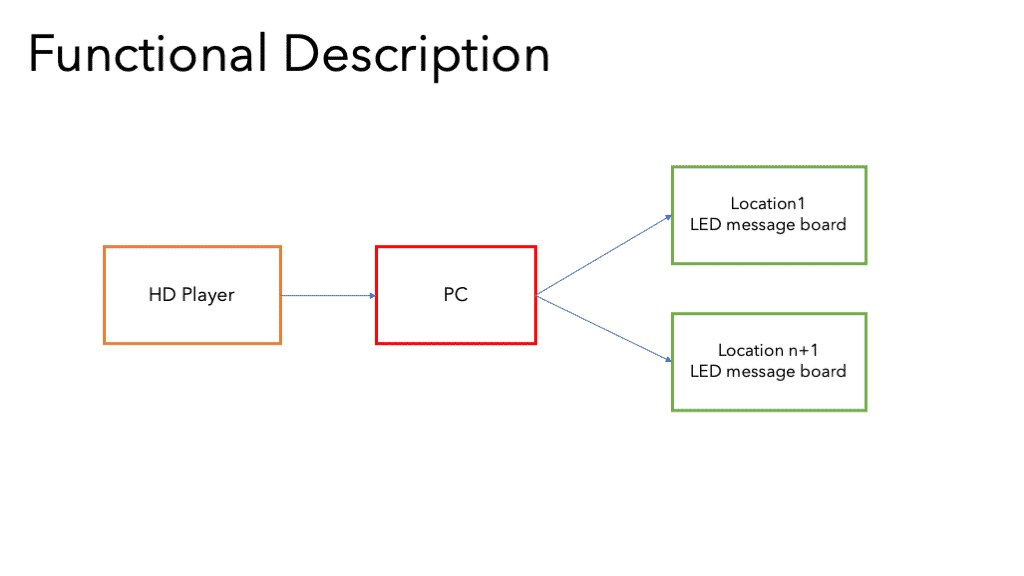

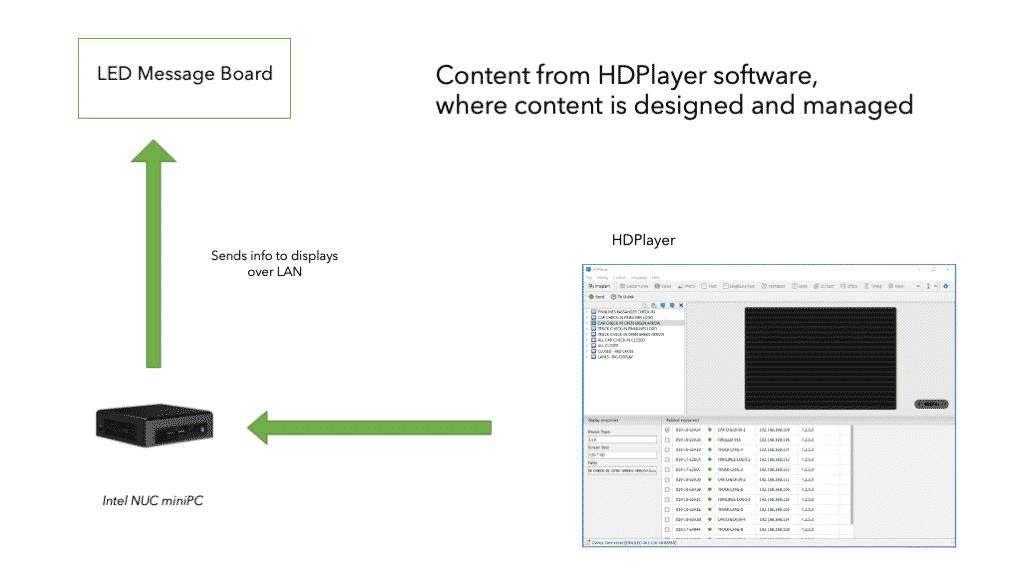

OPTION 3– Windows PC based software HDPlayer

Content is designed and managed from this software. Installation is local and may be installed onto multiple computers. Might be controlled over the cloud through windows remote control software.

The advantage is a simple way of starting the usage and in cases where the full automation is not yet thought through. Also the need for minimum hardware. Gives the option of playing procedures through in a first phase without complex integration project or investments.

For example, we have a port customer who wanted to direct truck drivers and passengers to the ferries. But they were not yet sure about the full automation solution and did not have the investments or human resources for the more complex project. So they decided to control the displays manually as the first phase. During this phase, they got to know how they would direct the truck drivers and what automation they would need. Now they are considering the second phase as to automate.

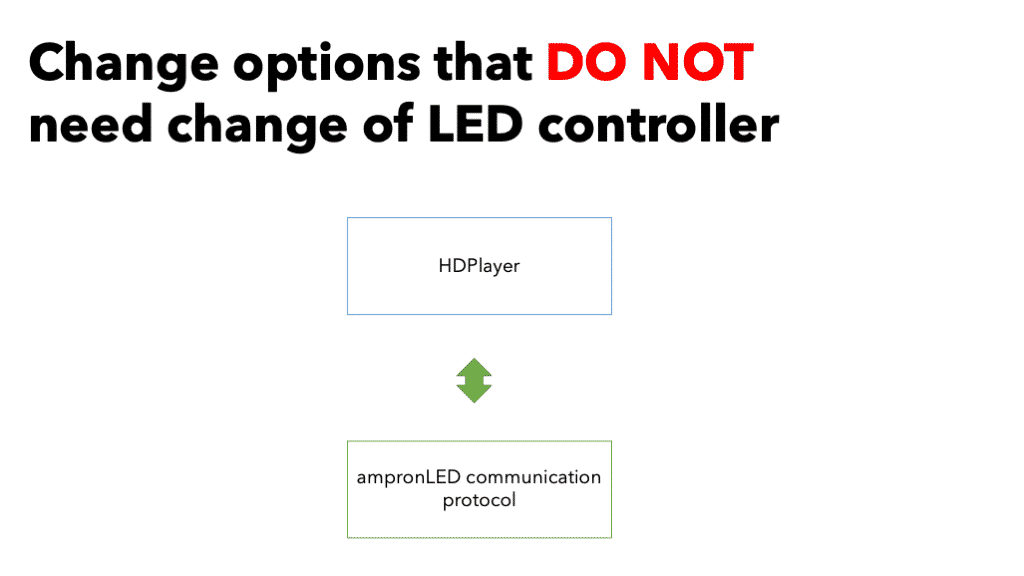

Downside of this control is the lack of automation possibilities. You may schedule the visuals but it lacks the options of changing content based on third-party software input. Good thing is that the upgrade to ampronLED communication protocol is really easy and needs no hardware upgrades or changes.

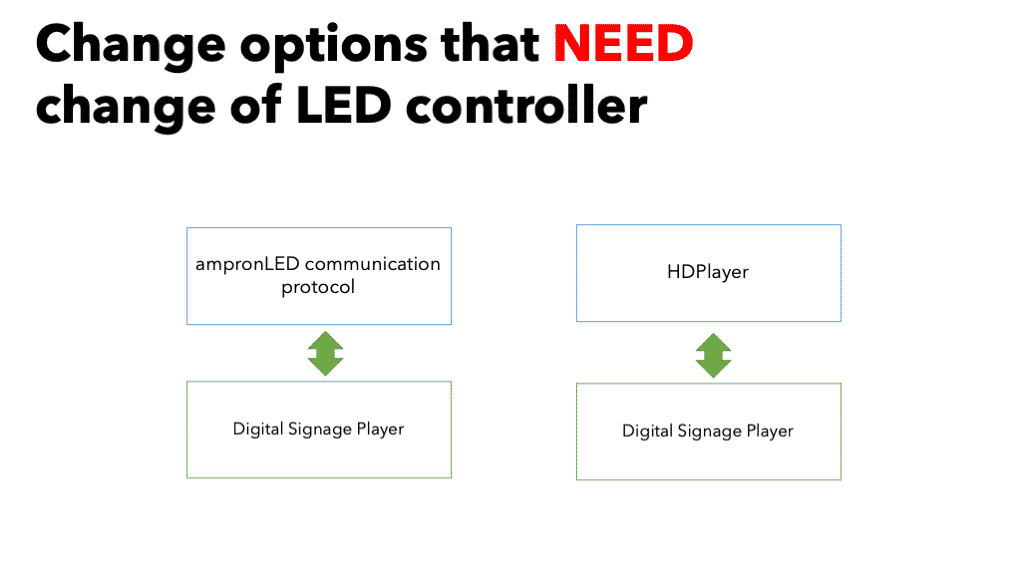

Future change options

You have flexible options with future upgrades or changes from one option to another. The only change you have to make is the change of the LED controller in some cases. Following is the illustration of the change cases.

Still not sure or tough to decide? Do not worry, contact us and ask additional questions or tell your story, we will try our best to simplify things for you and advise best suitable option.